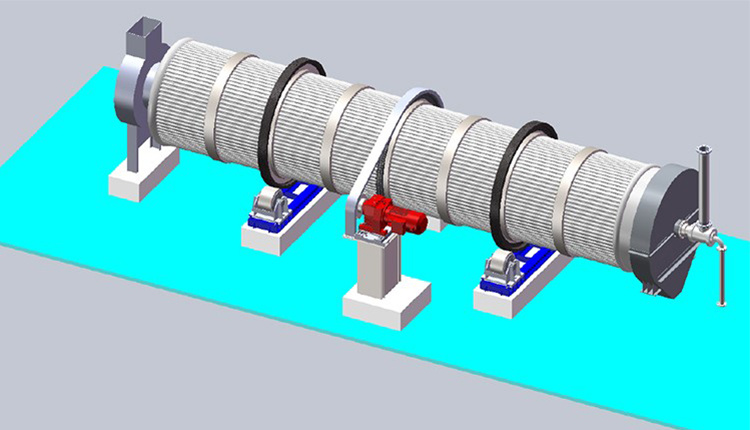

Maintenance of customized screw cooler for CFB boilers

Release time:

Jun 12,2022

The customized screw cooler for CFB boilers should be cleaned regularly, so that the compressor can work at a normal temperature to ensure a long service life of the machine. When the cooler is blocked, the exhaust temperature of the compressor will rise.

The customized screw cooler for CFB boilers should be cleaned regularly, so that the compressor can work at a normal temperature to ensure a long service life of the machine. When the cooler is blocked, the exhaust temperature of the compressor will rise. Generally, the outside of the customized screw cooler for CFB boilers should be cleaned every 1500 hours, and the water side of the cooler should be cleaned every 1500 hours. Regular cleaning of the cooler has the following benefits:

1. Make the customized screw cooler for CFB boilers always work at the ideal working temperature (below 95 ℃), which is good for the performance and life of the machine.

2. The dirt can be removed by using the cleaning liquid. Otherwise, when the dirt is thick, the cleaning work is quite troublesome, and the customized screw cooler for CFB boilers needs to be disassembled, and the cleaning work can be completed by means of mechanical methods.

Cleaning steps on the cooling medium side:

1. Stop the machine and confirm that the pressure has been released, and pull down the main power switch.

2. Open the air guide to clean the cover, or remove the cooling fan.

3. Blow back the dirt with compressed air, and then take the dirt out of the air guide hood; if it is dirty, spray some degreaser before blowing. When it cannot be cleaned by the above methods, the customized screw cooler for CFB boilers needs to be removed, soaked or sprayed with cleaning liquid and cleaned with a brush.

4. Install the cover or cooling fan.

Related News

Share