ABOUT SONGLING

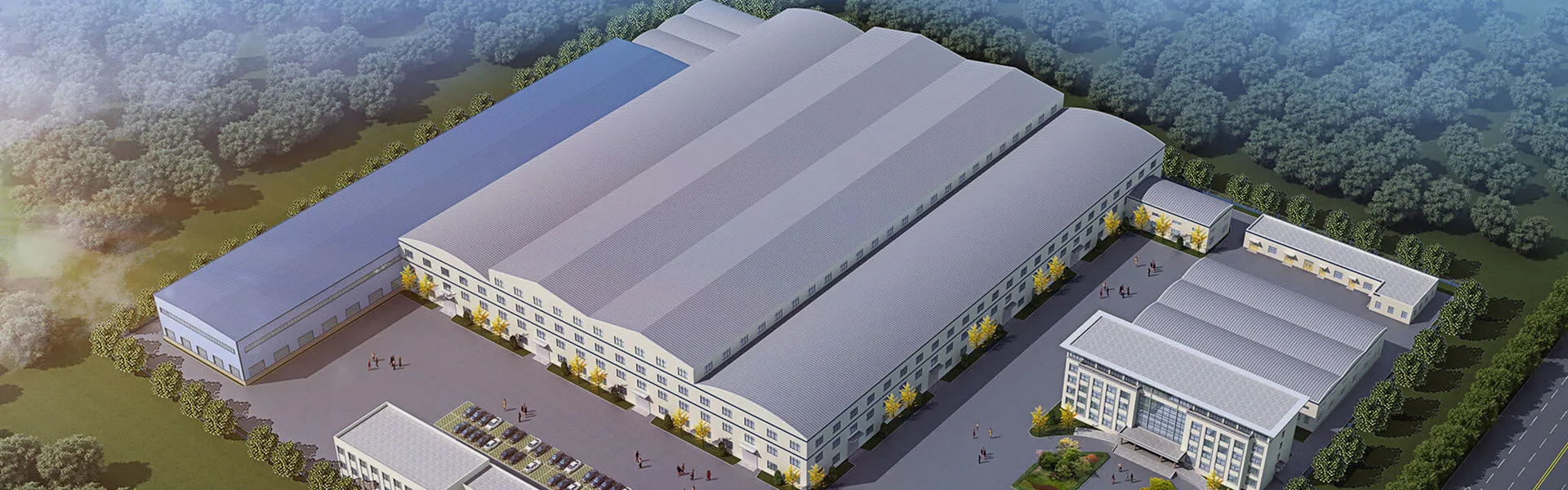

Qingdao SONGLING Power Environmental Equipment Co., Ltd. (SONGLING) was founded in 2002. It is the earliest manufacturer in China who engaged in the R&D, manufacture and sales of large-type rotary drum cooler. It is the R&D center and manufacturing base for large-type material coolers and dryers, and is devoting itself to be a world enterprise focusing on material cooling, drying and conveying solutions.

SONGLING’s main products include material cooling system, material drying system and material conveying system. SONGLING has innovatively developed large-type rotary drum cooler for global thermal power and needle coke fields, and provides solutions that can create value for customers in China and around the world in the fields of electricity, new energy, solid waste treatment, chemical, paper and pulp, mining, steel, metallurgy, etc. SONGLING also provides OEM/ODM customized equipment to some well-known international companies in relevant industries.

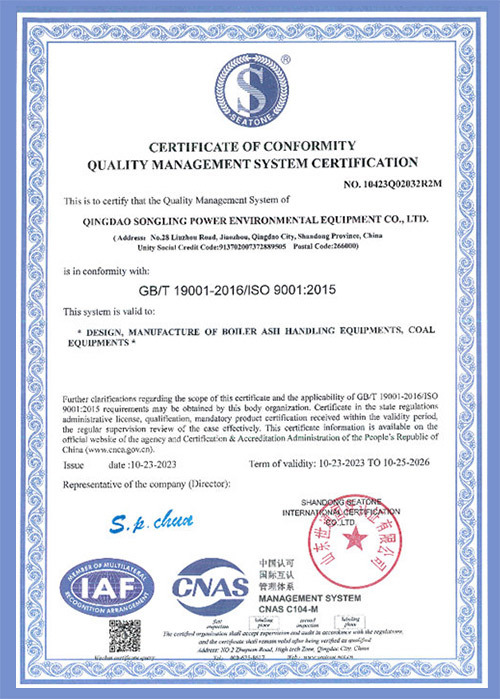

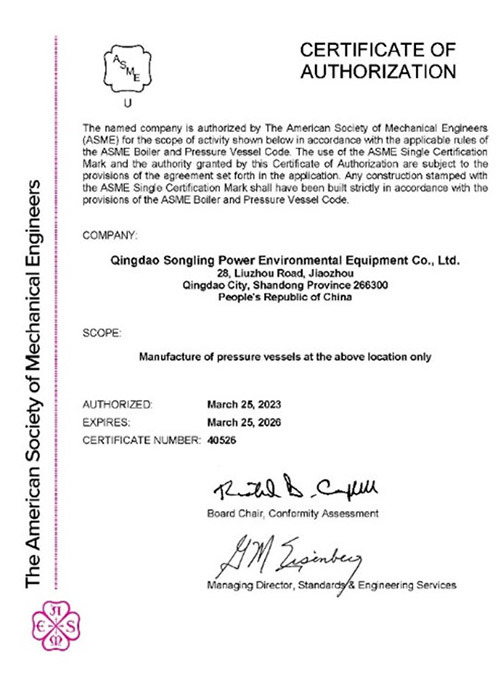

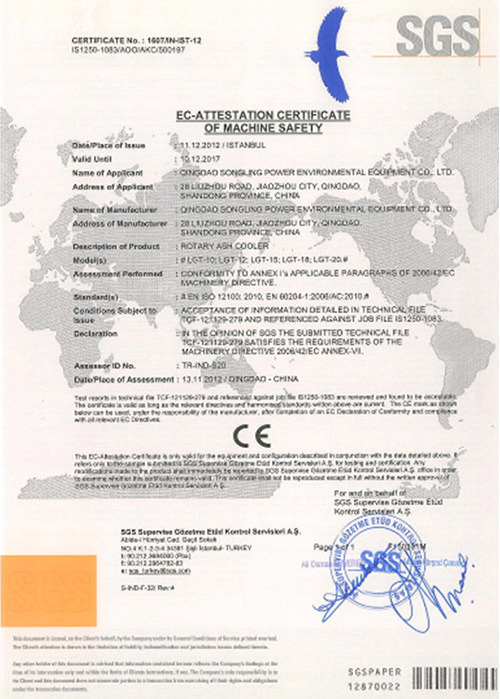

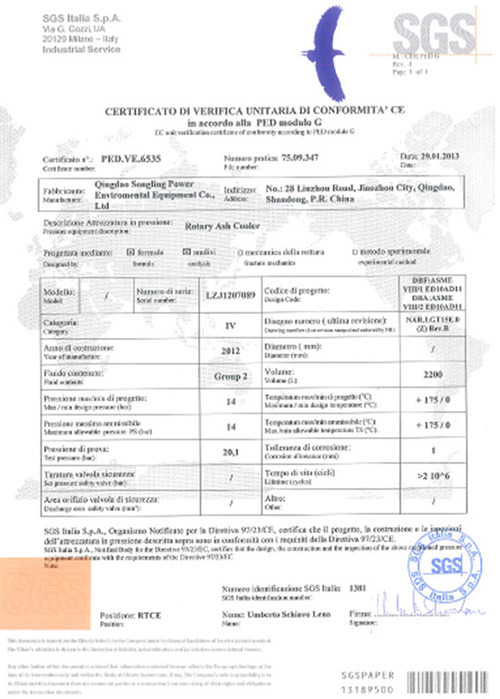

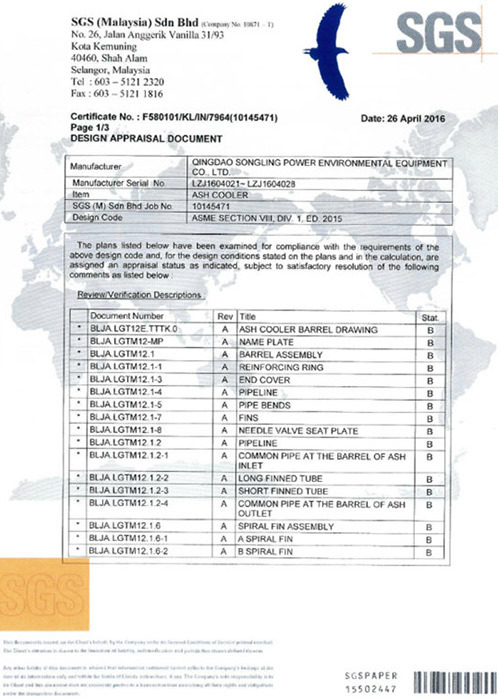

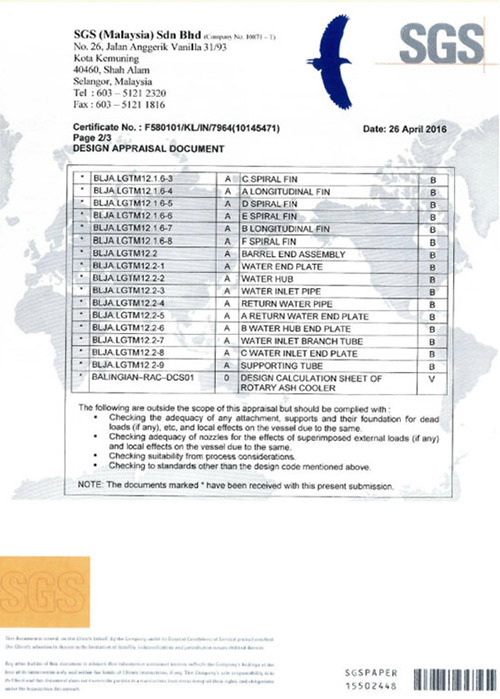

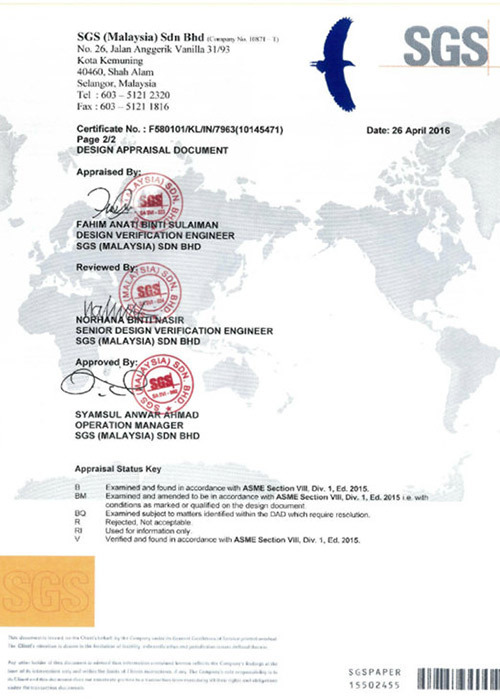

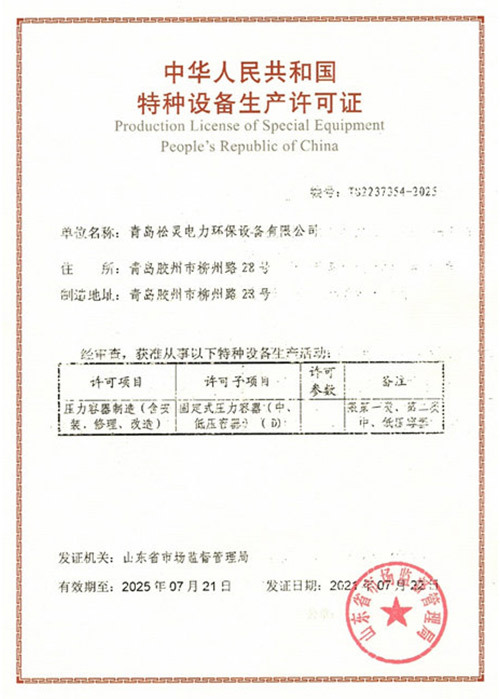

SONGLING has complete manufacturing and quality assurance system. It is certified and awarded with American Society of Mechanical Engineers (ASME) certificate for U stamp, EU CE certificate, Malaysia DOSH Certificate and Chinese pressure vessel production license. SONGLING’s products have been exported to over thirty countries and regions in Asia, Europe, North America, South America, Africa and Oceania.

SONGLING Vision

Core Value

People First

Collaborative Innovation

Create value for customers

Vision

Global R&D Center and Manufacturing Base for large material coolers and dryers

To be a world top enterprise focusing on material cooling, drying and conveying

Business divisions

POWER STATION

Business division

Business Scope:

Design, Engineering, manufacture, installation and commissioning of boiler bottom ash cooling, conveying system, heat recovery system

OVERSEAS

Business division

Business Scope:

Overseas market service, design, manufacture, installation and commissioning, steel structure OEM&ODM

SOLID WASTE

Business division

Business Scope:

Design, engineering, manufacture, installation and commissioning of sludge drying, coal slurry drying, solid waste resource utilization system, EPC contractor service

METALLURGY

Business division

Business Scope:

Design, engineering, manufacture, installation and commissioning of metallurgy, anode material, carbon cooling, drying, conveying and storage system

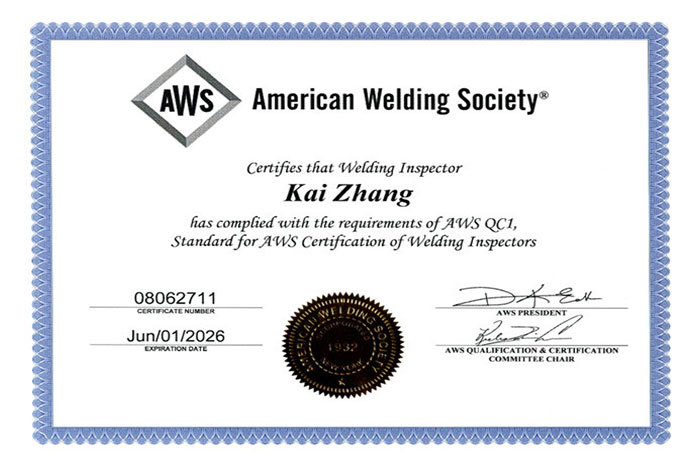

CERTIFICATION

Technical center

Technical Engineers

70 +

Patent Certificates

200 +

National

High-tech Enterprise

Provincial

Technical Center

Manufacturing Capacity

Welding Team

Welding Engineer: 2 persons

Certified Welder: 11 persons for TSG Z6002-2010 Standard

30 persons for ASME Code

11 persons for EN287-1

22 persons for AWS D1.1

Testing Team

VT Inspector: 8 persons

NDE upon JB/T4730-2005: 3 persons

NDE upon EN473: 2 persons

NDE upon ASME: 2 persons

NDE upon AWS: 1 person

Manufacturing Workers

200 +

Manufacturing Facilities

50 +