Advanced Cooling Innovation: China Rotary Kiln Cooler by SONGLING

Release time:

Jul 31,2025

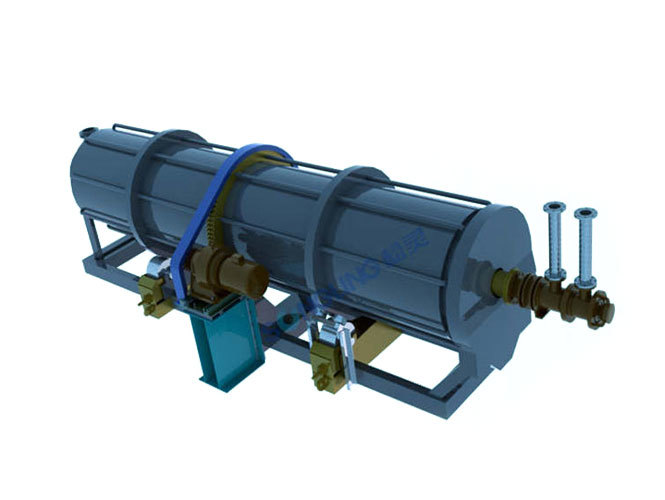

The China rotary kiln cooler, especially the rotary drum cooler developed by SONGLING, represents a major breakthrough in thermal processing and cooling technology for high-temperature bulk materials.

The China rotary kiln cooler, especially the rotary drum cooler developed by SONGLING, represents a major breakthrough in thermal processing and cooling technology for high-temperature bulk materials. Invented and patented in China, this system is engineered for efficient cooling of materials such as Calcined Coke, Semicoke, Needle Coke, Graphite Anode Materials, Magnesium Reduction Residues, Steel Slags, and Manganese Reduction Products.

The rotary kiln cooler consists of a robust rotating drum with dual-layered cylinders: an outer shell with membrane pipes and an inner section with specially designed tubes. Inside the drum, guide fins direct the hot materials toward the outlet while transferring heat to the integrated cooling water system. As hot materials enter the bottom of the drum, they form a balanced flow controlled by gravity and material resistance. The rotating speed directly influences material throughput, offering precise control of cooling capacity.

What sets the China rotary kiln cooler apart is its intelligent design and patented technologies. SONGLING’s innovations include:

Patented roller support and seal system for reliable, long-term operation.

Patented water inlet station that ensures consistent cooling efficiency.

DCS-controlled variable frequency motor that adjusts cooling based on process needs.

Low auxiliary power consumption, making it an energy-efficient solution.

Minimal wear and tear due to the absence of mechanical pushing forces.

Unlike traditional cooling systems, the SONGLING rotary drum cooler is insensitive to variations in material size and properties, making it ideal for diverse industrial applications. The unique internal fin structure—both spiral and longitudinal—not only lifts and moves solids efficiently but also ensures uniform cooling with minimal erosion on the drum’s components.

Furthermore, the system is designed with easy online inspection and maintenance, reducing downtime and enhancing operational reliability.

In summary, the China rotary kiln cooler by SONGLING is a next-generation cooling solution tailored for heavy-duty industrial use. Its advanced engineering, proven performance, and smart automation make it a preferred choice in the global market for cooling calcined and metallurgical materials.

Related News

Share